Automatic AAC Block Manufacture Direct Selling AAC Block Machine

Basic Info

Model No.: AAC

Product Description

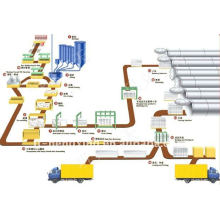

AAC Block Equipments, Aac Block Machine ,Aerated Concrete Block Making Machine 300,000m3/year, 200,000m3/year, 150,000m3/year, 100,000m3/year,etc Product Description AAC Block forming process 1 The Preparing of The Raw Materials A. The Preparing of The Slurry B. The Preparing of The Lime C. Cement D. Stone Powder E. Waste material 2. Batching, Mixing, Pouring 3. Resting and Pre-curing 4. Demoulding, Cutting, Grouping 5. Curing, Finished Product Leaving Autoclave 6. The Reclaim System of Waste Water & Slurry Planning and Design:

Factory covers an area of 25 acres or so.

There should be raw material area, finished block area and production area. Production process includes raw material disposal, rated material pouring, curing, cutting and steaming procedure.

From building foundation to equipments installing and testing, to trial producing, it will take 4-5 months. Plant design: 2000 m2 or so. Material:

1. Flyash: get dry ash from power plant

2. Cement: cement in bulk

3. Lime, gypsum and aluminum powder (buy in local area) Water, electricity and steam supply:

1. Water supply: build a well or use waste water

2. Electricity supply: install a 315kv transformer Product quality and specification

Quality

We produce according to PRC standard GB11968-1997 “Aerated Autoclaved Concrete Block Technology”. Machine advantages (1)light weight Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking. (2) keeping temperature It has many are porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world.There are many kinds material,have lowest waste. (3)High Strength High pressure steam-curing autoclaving process gives AAC unmatchable strength to weight ratio, higher than even M150 concrete and far exceeds the Indian Building code requirements (4)Cost saving Being lightweight AAC drastically reduces the dead weight of building, resulting into reduction in steel (up to 27%) and cement (up to 20%) structural cost saving.Being 8 times the size of a clay brick, AAC wall construction involves 1/3 the joints, thus an overall mortar saving up to 66% Produce process

Contact us if you need more details on Aac Block Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aac Block Manufacturer、Fly Ash Brick Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Aac Block Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aac Block Manufacturer、Fly Ash Brick Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Factory covers an area of 25 acres or so.

There should be raw material area, finished block area and production area. Production process includes raw material disposal, rated material pouring, curing, cutting and steaming procedure.

From building foundation to equipments installing and testing, to trial producing, it will take 4-5 months. Plant design: 2000 m2 or so. Material:

1. Flyash: get dry ash from power plant

2. Cement: cement in bulk

3. Lime, gypsum and aluminum powder (buy in local area) Water, electricity and steam supply:

1. Water supply: build a well or use waste water

2. Electricity supply: install a 315kv transformer Product quality and specification

Quality

We produce according to PRC standard GB11968-1997 “Aerated Autoclaved Concrete Block Technology”. Machine advantages (1)light weight Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking. (2) keeping temperature It has many are porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world.There are many kinds material,have lowest waste. (3)High Strength High pressure steam-curing autoclaving process gives AAC unmatchable strength to weight ratio, higher than even M150 concrete and far exceeds the Indian Building code requirements (4)Cost saving Being lightweight AAC drastically reduces the dead weight of building, resulting into reduction in steel (up to 27%) and cement (up to 20%) structural cost saving.Being 8 times the size of a clay brick, AAC wall construction involves 1/3 the joints, thus an overall mortar saving up to 66% Produce process

Contact us if you need more details on Aac Block Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aac Block Manufacturer、Fly Ash Brick Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Aac Block Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aac Block Manufacturer、Fly Ash Brick Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Autoclaved Aerated Concrete Production Line (AAC)

Other Products

Hot Products

YHZS50 Portable Concrete Batching Plant For SaleAssembly 100ton steel cement silo for cement storagePut in container 35 tons horizontal cement siloEfficiency!! MD 1200 30m3/h Concrete Batching Plant for constructioncement silo,stainless steel silos,mobile cement siloHorizontal cement silo,mobile cement silo,portable cement siloDOM silo,horizontal silo,mobile cement silo,portable silo for saleEngineers Available To Service Overseas Mix Concrete Mixing Plant Ready SaleMC1800 small portable concrete mixing plantMB1200 mobile concrete batching plantConcrete batching plant big bag cement silo 3m3Stabilized Soil Concrete Mixing Plant for SaleHot sale asphalt mixer mixing plant asphalt equipment for saleHigh Quality Small Concrete Mixer Machine Mobile Concrete Mixing PlantFly Ash AAC Block Machine Production Line(HZS Series) Low Price Products Concrete Batching Plant Concrete Mixing Plant