Concrete Cement Silo Cost for Concrete Plant

Basic Info

Model No.: SNC150

Product Description

Description of Concrete Cement Silo for Concrete Plant

The whole or flake cement Silo is one optional parts of the Concrete Batching Plant or Mobile Concrete Plant . Most of the customers will order Cement Silos together with the concrete plant . also some customers thinkit is more ecomonic to buy it local. Shine concrete cement silo is suitable for storing bulk materials such as grains, cement, powder and fly ash. Material level system is installed in the tanks, which can show the position and quantity of the materials. The hole device can clear up hard materials from long sediment. The materials can be sent to all the positions with the combination of cement bin and Screw Conveyor pump. Easy installation with its characteristics of safety and reliability makes it an ideal cement bin for the Concrete Mixing Plant.

Shine Machinery Cement silo Advantages

1. With different capacities:50T,100T,150T,200T,etc.

2. Customized sizing and layout to specific requirement

3. Sub-structure, easy transportation, installation fast, level display, with positive and negative regulator,Green filter

4. Put in bulk powder (cement or fly ash), waterproof and moisture, easy to use and reduce costs , the top of cement silo with green filter, used to reduce dust leakage.

5. Equipped with a Safety Valve at the top of cement silo, cement silo used to balance the pressure difference between inside and outside. Upper and lower parts of the cement silo is equipped with display materials, can monitor the number of cement materials warehouse. With gas in the lower part of broken cement storage devices, to ensure smooth unloading.

Technical Parameter of Bulk Cement Silo for Construction

Item 50t 100t 150t 200t 300t Tank Height (m) 4.5 9 13.5 9 8.25 Tank Diameter (m) 3 3 3 4.5 5.5 Tank Section quantity 3 6 9 6 5.5 Cone Height (m) 2.6 2.6 2.6 3.8 4.8 Discharging Discharging height (m) ≥1.5 ≥1.5 ≥1.5 ≥1.5 ≥1.5 Cone Landing leg height (m) ≥4.1 ≥4.1 ≥4.1 ≥5.3 ≥6.3

FAQ

1.Q: What is the productivity of Concrete Mixer and concrete Batching Plant?A: The productivity of concrete batching plant ranges from 25m3/h to 180m3/h.

2.Q: How many wheels does Mobile Concrete Batching Plant have? Is it movable ?

A: Two wheels. It is movable.

3.Q: What is the type of Mixer in concrete batching plant?

A: Planetary shaft type concrete mixer and horizontal twin-shaft type concrete mixer are all can be used in concrete batching plant. We are the expert of horizontal twin-shaft type concrete mixer.

4.Q: Is PLC fully automatic or semi automatic?

A: They can be fully automatic and semi automatic. According to our experience, we recommend fully automatic ones. It is easier to operate fully automatic ones to save labour cost.

5.Q: Warranty period your company giving for products?

A: 12 months after installation.

6.Q: Operating system warranty and any extra unit with plant?

A: Operating system and any extra unit warranty: 12 months after installation.

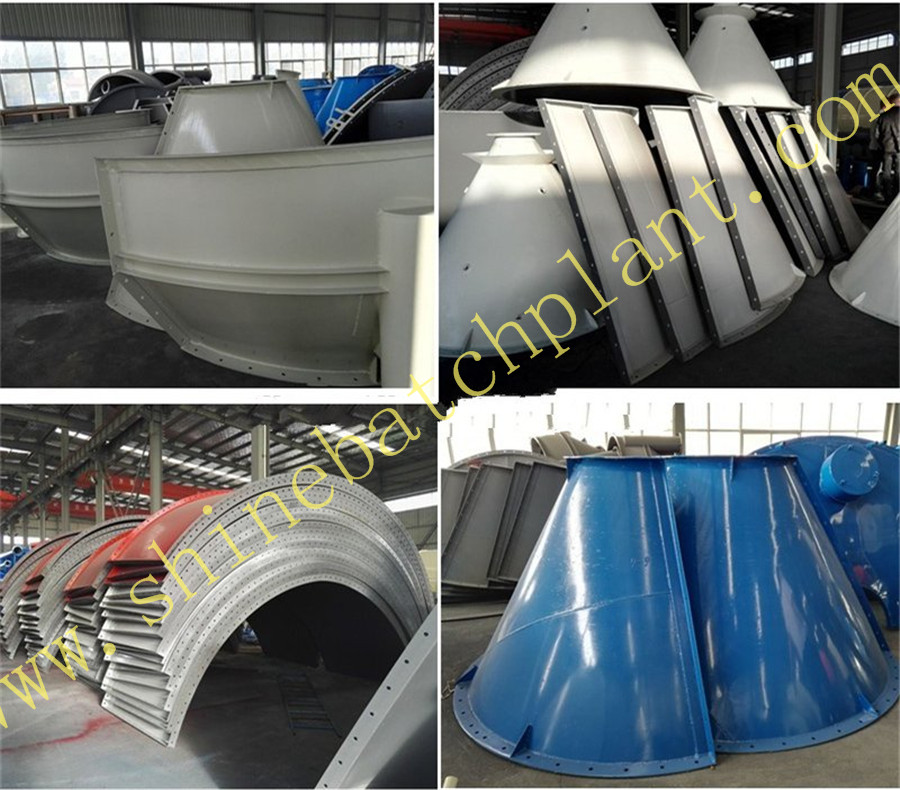

More Pictures of Shine Cement Silo

Product Categories : Concrete Batch Plant Accessories > Cement Silo