Asphalt Concrete Pavement plant

Basic Info

Model No.: GYXL1606

Product Description

GYXL1606 Asphalt Rubber Plant

GYXL1606 asphalt rubber plant adopts computer to control the precise proportioning of materials easily and stably. It is capable to produce asphalt rubber stably, successively and efficiently. The finished asphalt rubber is featured by high-temperature stability, low-temperature flexibility, properties of aging resistance, endurance resistance and water resistance. Therefore, asphalt rubber is widely applied in express highway construction.

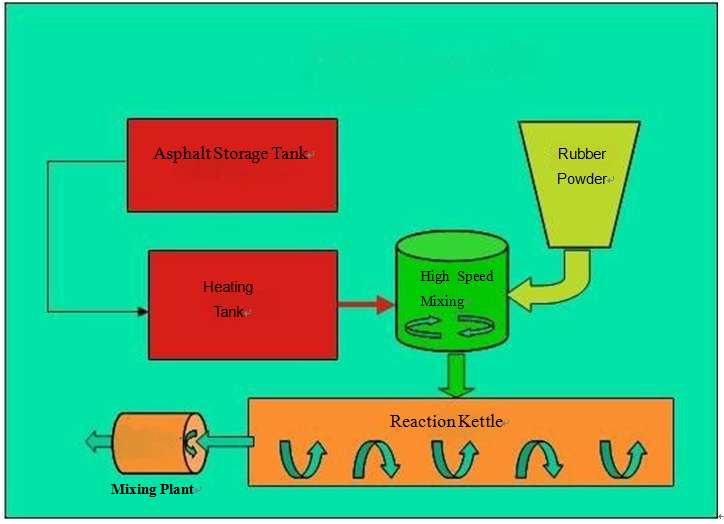

Technological Process

The rubber power is feeded into the rubber powder bin and scattered by the crashing device at the bottom of bin; then rubber power is delivered by spiral conveyor to continuous mixing and high-speed cutting device of rubber power and matrix asphalt. Synchronously, matrix asphalt is pumped out of tank, then through the filter (optional device) in front of asphalt pump and delivered into matrix asphalt heating-up device; heat transports from heat oil of high temperature in heat exchanger to matrix asphalt, which makes matrix asphalt temperature increase to the specified numbers in very short time. Next, the high-temperature matrix asphalt also goes into the continuous mixing and high-speed cutting device for mixing and cutting evenly to form mixtures with rubber powder; after mixing, the mixture is pumped into reaction kettle which is equipped with forceful stirring device, heating device and heat oil pipeline thermal isolation system for 45-60 minutes reaction until the viscosity and other properties of finished asphalt rubber meeting the required specification. Finally, finished asphalt rubber will be pumped out of kettle to mixing plant for application or asphalt tank for storage.

Main Components & Function

Item Function & Technical Data

Rubber Powder Batching System It consist of hopper, crashing device and spiral burdening device, conveying measured rubber powder to the rubber powder and asphalt continuous mixing and high-speed cutting device; spiral feeding device is regulated by electrical proportional valve

Matrix Asphalt Heating-up Device Heat exchanger of large area and cross circulation transfers, heat through heat oil to heat up the matrix asphalt for 40-65℃ at the speed of 8t/h in the interval of heat exchanger circulation

Rubber Powder & Asphalt Continuous Mixing & High-speed Cutting Device Mixing the metered rubber powder and asphalt well, which realizes rotary speed of 2900rpm at home only; patented high-speed rotary cutting device scatters the rubber crumb blocks and distributes the rubber powder evenly in the binders to stabilize the binders` technical.

Reaction Kettle Mixtures reaction vessel; special powerful Mixer prevents asphalt rubber from segregation in the tank and makes favor of complete mixed reaction; speeding up heat transfer to make full use of heat energy for reduction of production costs; double heating system includes heat oil coil and fire tube heated by diesel burner; thermal insulation device keep the required temperature for reaction; external heats asphalt up more rapidly.

Automatic Electrical Control System Controlling and monitoring the operation of the whole machine, computer design, and automatic control. Humanity design improves comfort experience in the operations.

Pump valve pipe system Each pump valve pipe heat tracing in whole course

Technical Parameters & Configurations:

Item Parameters Unit Model GYXL1606 Productivity 6 t/h Total Installed Power 120 Kw Fast Heating-up Device Heating capacity 80x104 kcal Heat exchange area 1*32 M2 Heat exchange coefficient 50(20t/h) ℃ Measuring Precision ≤0.5 % Rubber Powder Feeding System Rubber powder measuring precision ≤0.5 % Max. capacity of helical feeder 10 m3/h Base Asphalt System Max. flow rate 1300 l/min Rubber Powder & Asphalt Mixer Mixer rotary speed 2900 rpm Mixer power 11 Kw Capacity ≧40 m3/h Reaction Kettle Heating power of burner 1x20x104 kcal Kettle capacity 1*17.5 m3 Max. conveying capacity of asphalt rubber pump 40 m3/h Mixing speed 198 rpm Mixing power 11 Kw

Product Categories : Asphalt Production Plant > Rubber Asphalt Plant