Galvanized Steel Spiral Grain Bin Silo Machine

Basic Info

Model No.: TG-0173

Product Description

The Spiral Grain Bin Silo Machine unique manufacturing process of the spiral steel silo, the equipment is in place, the 495mm wide coiled silo is sent to the forming machine by the uncoiler, and the required geometry is formed and sent to the outside of the silo. Form a continuous spiral belt with a width of 30-40mm and a thickness of 5 times that of the base metal, and the support wheel will automatically lift the warehouse to the required height and then drop the bin. Spiral Grain Bin Silo Forming Machine Good overall performance, long life, good air tight performance, wide application, Spiral Grain Silo Forming Machine short construction period, low cost, small floor space and easy management

The Spiral Silo Grain Storage Machine has become an important storage facility for storage and transportation and modern logistics. Grain Silo Bin Machine are widely used for the transport and storage of solid particles, solid powders and liquids. The Steel Silo Roll Forming Machine are used widely 1. Spiral Steel Silo Roll Forming Machine Material shape (storage): granular material, powder material, liquid material 2. LIPP Spiral Coiling Equipment Industry: grain, feed brewing, oil, medicine, food, cement, water treatmen 3. Rolling Sprial Steel Silo Forming Machine Concrete variety(storage): wheat, soybean, maize, sorghum wheat flour, bulk cement fly-ash, sewage, water, chemical syrup

1. Profile Drawing and Products for Reference

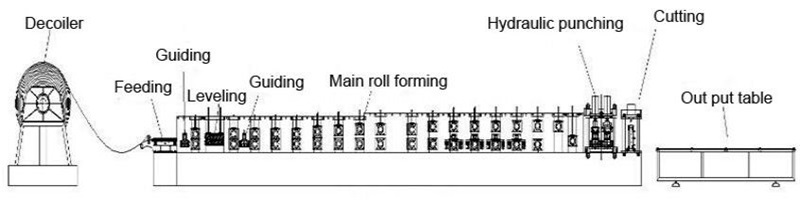

2. Production Process

De-coiler- feeding with guide→ Straightening device→ main roll forming machine→ Curving device→ run out table

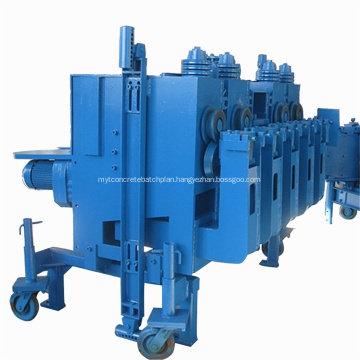

3. Constituent part

4. Machine List

| Name | Quantity |

| hydraulic decoiler(optional) | 1 set |

| Feeding&leveling device | 1 set |

| Main forming machine | 1 set |

| Gear box drive system | 1 set |

| Curving device | 1 set |

| Hydraulic Cutting device | 1 set |

| PLC control system | 1 set |

| Hydraulic station | 1 set |

| Auto stacker 6 meters(optional) | 1 set |

5. Silo Roll Forming Machine Overview

6. Scene application

7. Customer

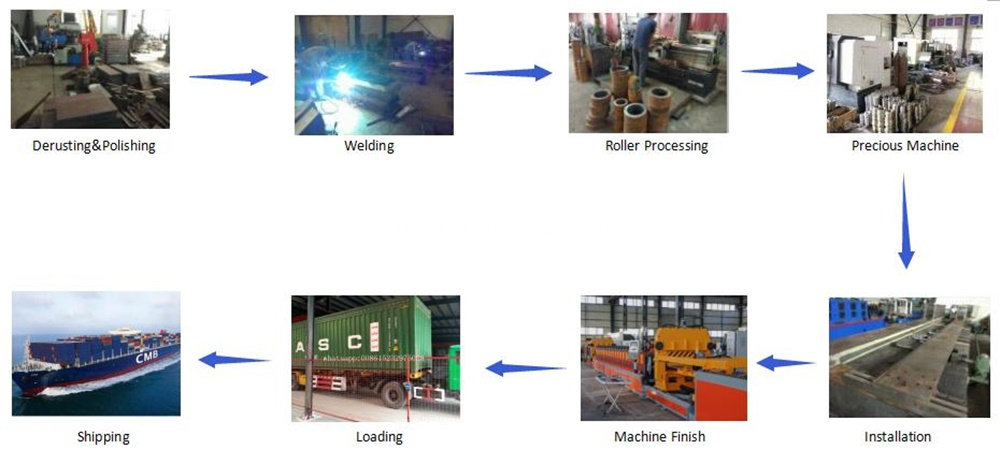

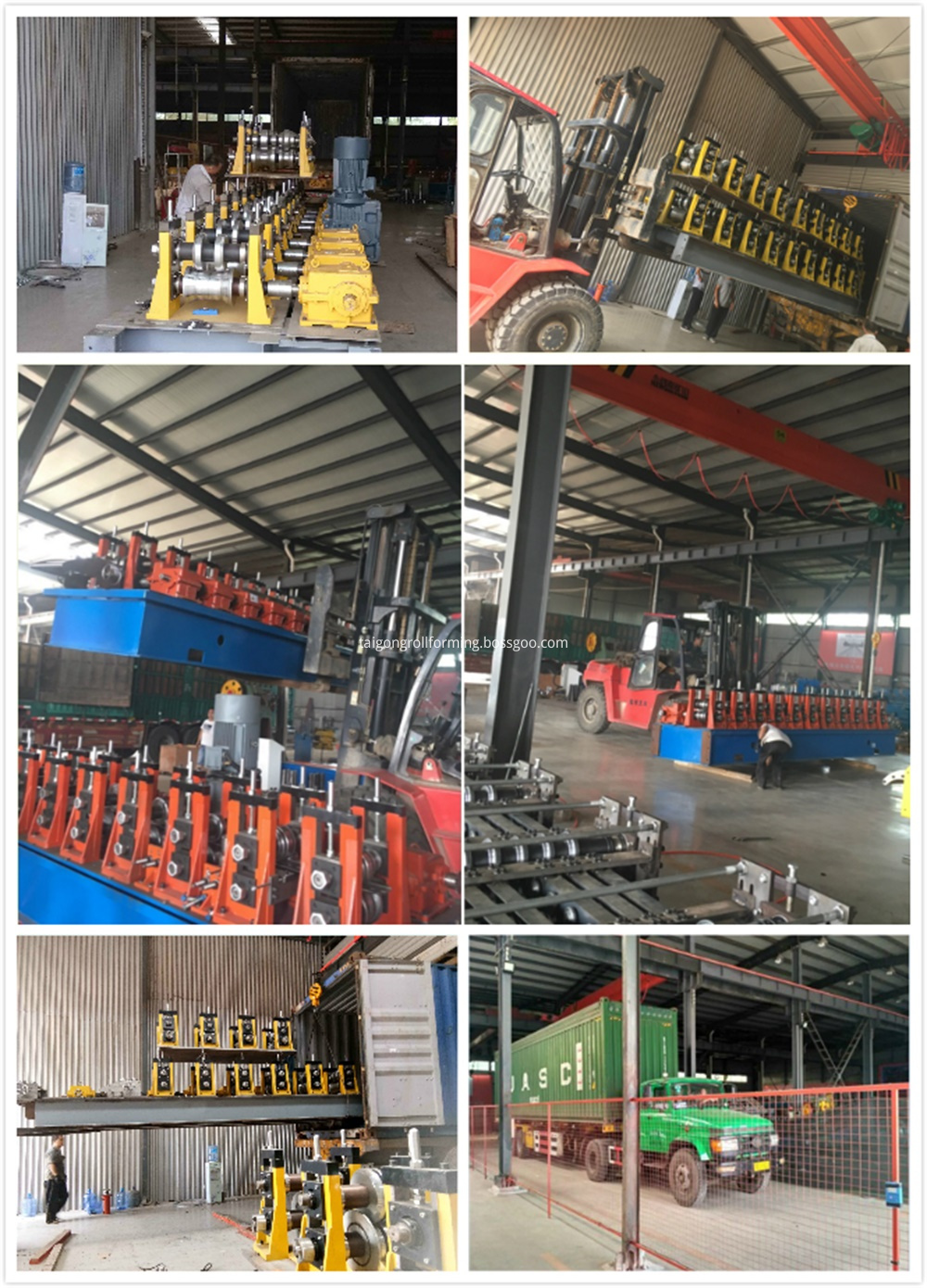

9. Loading

10. Payment terms and after-sale service

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping Grain Bin Machine

3) Delivery time: Silo Machine 45-50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping Helix Steel Silo Making Machine cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training

1. If buyers visit our factory and check Helix Steel Silo Forming Machine, we will teach you how to install and us the Spiral Steel Silo Roll Forming Machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual or video to teach you to install and operate Silo Roll Forming Machine

The buyer should pay the installation charges (USD 100 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Product Categories : Silo Roll Forming Machine > Spiral Steel Silo Roll Forming Machine