Light Weight Brick Making Machine

Basic Info

Model No.: HXM-AAC

Product Description

Specifications Light Weight Brick Making Machine

Mitsubishi PLC with excellent protection of contril system

Schneider electric components

Light Weight Brick Making Machine/ AAC (Autoclaved Aerated Concrete) Introduction: HXM designs and manufactures AAC block making plant, to meet the specific requirements of the market and cutstomers. As a new building material, AAC block fulfills the demand of concrete industry, which requires to save the natural resources and protect the environment. With Germany technology and our own R&D, we provide our customers state-the-art AAC block making plant 1. Market Analysis AAC is becoming more and more popular around the world, from western countries and then to developing countries. Below Properties make AAC have unmatchable property, especially for high buildings: 1) Extreme Light Weight 2) Large Variety of Sizes 3) High Fire Resistant 4) Excellent Thermal Insulation 5) Great Sound Insulation 6) Moisture Protection 7) Termite Resistant 8) High Workability and Easy Processing HXM Advantages: Control System: Mitsubishi PLC, main electrical components are from Mitsubishi, its weighing system are controlled by precise weighing system, guarantee the weighing accuracy. The accuracy will effect the qualified product rate, higher accuracy, higher qualified produce rate. Steal Silo storage, automatically control with arch breaker, level indicator. With quality and service: A-Z Integrated solution for AAC brick making plant, the highly sophisticated manufacturing process. HXM Light Weight Brick Making Machine/AAC Capacity:

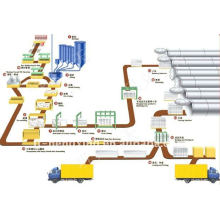

2. Light Weight Brick Making Machine details: AAC is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder ect., through batching, mixing, casting ,cuttimg and autoclaving. AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great scousitc insulation and high fire resistance. AAC can be produced in a large variety of sizes, from stand blocks to large reinforced panels, and it can be cut, sawn ,drilled ,nailed and milled like wood, making it an extremely workable product, AAC is environment-friendly and new building material. Areated concrete brick (light brick ) is the light and porous buidling material. It has light weight keeping temperature cant burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely. Areated concrete common conception Common concrete density is usually 1600-2400kg/m3,but Areated concrete are 500kg/m3,600kg/m3,700kg/m3.It has not the big grain,main use silicon material (for example:coal ash,sand,stone dust and others ),through making the material small for example sand,they can be used directly if has enough degree of small (for example coal ash.Mixing calcium material lime cement water to a special slop,then add the aluminum dust and the additive.Make the aluminum dust and the special slop have a Chemical reflect.then produce Hydrogen to make the concrete slop to expanding or swell,foam.Next,put them into the curing room to concreting cutting steaming curing,last,there will bacome the light brick,the porous rate is 70-80%. 3.Advantages Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking. keeping temperature. It has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials. Light Weight Brick Making Machine Display:  Contact us if you need more details on Brick Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Weightless Brick Making Machine、Aac Brick Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Brick Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Weightless Brick Making Machine、Aac Brick Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Mitsubishi PLC with excellent protection of contril system

Schneider electric components

Light Weight Brick Making Machine/ AAC (Autoclaved Aerated Concrete) Introduction: HXM designs and manufactures AAC block making plant, to meet the specific requirements of the market and cutstomers. As a new building material, AAC block fulfills the demand of concrete industry, which requires to save the natural resources and protect the environment. With Germany technology and our own R&D, we provide our customers state-the-art AAC block making plant 1. Market Analysis AAC is becoming more and more popular around the world, from western countries and then to developing countries. Below Properties make AAC have unmatchable property, especially for high buildings: 1) Extreme Light Weight 2) Large Variety of Sizes 3) High Fire Resistant 4) Excellent Thermal Insulation 5) Great Sound Insulation 6) Moisture Protection 7) Termite Resistant 8) High Workability and Easy Processing HXM Advantages: Control System: Mitsubishi PLC, main electrical components are from Mitsubishi, its weighing system are controlled by precise weighing system, guarantee the weighing accuracy. The accuracy will effect the qualified product rate, higher accuracy, higher qualified produce rate. Steal Silo storage, automatically control with arch breaker, level indicator. With quality and service: A-Z Integrated solution for AAC brick making plant, the highly sophisticated manufacturing process. HXM Light Weight Brick Making Machine/AAC Capacity:

Annual Capacity(300days) | Power | Daily Capacity | Cycle Time | No. of Autoclaves |

50,000m³/year | 400KW | 166 m³/day | 10 hours | 2 |

100,000m³/year | 500KW | 333m³/day | 10 hours | 4 |

150,000m³/year | 630KW | 500m³/day | 10 hours | 6 |

200,000m³/year | 720KW | 666m³/day | 10 hours | 8 |

300,000m³/year | 1186KW | 1000m³/day | 10 hours | 6(D2.85*32.5) |

Contact us if you need more details on Brick Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Weightless Brick Making Machine、Aac Brick Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Brick Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Weightless Brick Making Machine、Aac Brick Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Autoclaved Aerated Concrete Production Line (AAC)

Other Products

Hot Products

YHZS50 Portable Concrete Batching Plant For SaleAssembly 100ton steel cement silo for cement storagePut in container 35 tons horizontal cement siloEfficiency!! MD 1200 30m3/h Concrete Batching Plant for constructioncement silo,stainless steel silos,mobile cement siloHorizontal cement silo,mobile cement silo,portable cement siloDOM silo,horizontal silo,mobile cement silo,portable silo for saleEngineers Available To Service Overseas Mix Concrete Mixing Plant Ready SaleMC1800 small portable concrete mixing plantMB1200 mobile concrete batching plantConcrete batching plant big bag cement silo 3m3Stabilized Soil Concrete Mixing Plant for SaleHot sale asphalt mixer mixing plant asphalt equipment for saleHigh Quality Small Concrete Mixer Machine Mobile Concrete Mixing PlantFly Ash AAC Block Machine Production Line(HZS Series) Low Price Products Concrete Batching Plant Concrete Mixing Plant